Noise Cancelling Stethoscope: Engineering Design Capstone

This was built as part of the our Carnegie Mellon Mechanical Engineering capstone project. Our team was challenged with creating a product that would improve the functionality of an everyday product. One group member was an EMT and noted that stethoscopes are used daily by medical professionals, but have much room for improvement.

Our group decided to focus on building a noise-cancelling stethoscope, integrating an existing stethoscope head with a passive noise-cancelling earpiece. We interviewed medical professionals to see what their requirements were: "lightweight," "easy to use," "durable," and "portable" were all common responses. Using tools like the House of Quality and Pugh Charts, our team designed a noise-attenuating headset that would be compatible with common stethoscope brands.

Our proof-of-concept was built with off-the-shelf components, and our final prototype was 3D printed. Our final design featured noise-attenuating chambers, flexible earpieces to allow for users to wear the stethoscope in various orientations, and a foldable design that would fit in most pockets. Our headset design was also designed to withstand several flexing cycles and, using FEA, we determined our product to withstand typical stresses seen when using a stethoscope.

I was responsible for much of the CAD drafting, FEA, and noise simulation. Noise simulation tests were conducted in common usage scenarios: ambulance sirens and crowd noise. In each cases, our prototype cut out a significant amount of high-frequency noise compared to a traditional stethoscope, allowing our product to sense low-frequency heartbeats clearly.

Sketch of envisioned usage of this stethoscope: in the "headphones" orientation and in the "stethoscope" orientation.

Our proof of concept device, made from off-the-shelf parts. This model functioned but did not have the rotation capabilities, nor did it have the durability we were looking for.

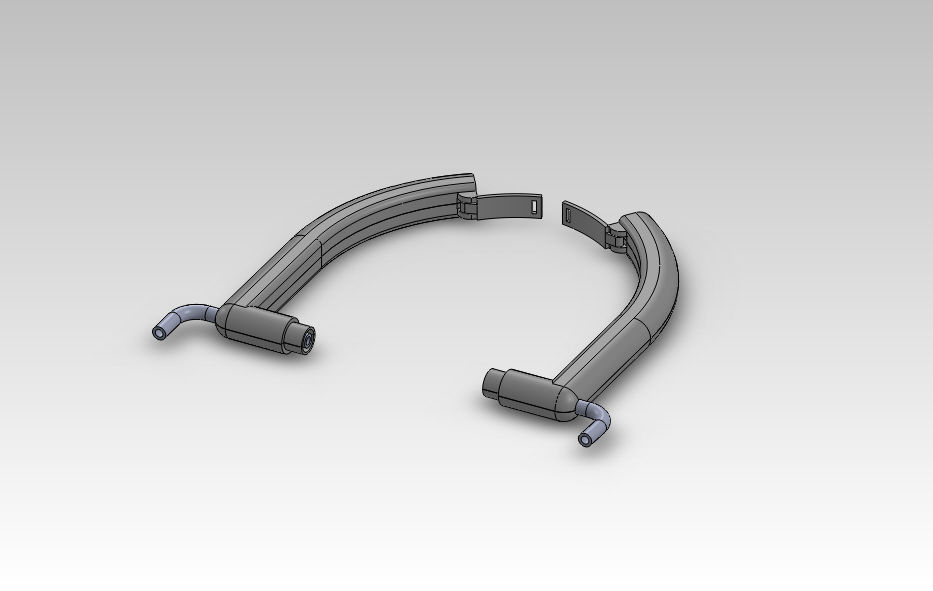

CAD of the first prototype, complete with rotating earpieces. The hinge would later be redesigned to have a replaceable headband.

Exploded view of the final prototype. This model is mostly 3D printed ABS with some off-the-shelf components. Note the changes to the hinge from the CAD.

Our final assembly, which was used in noise testing and displayed at our class presentation that was featured on the local news.

Our device in the "folded" configuration. The flexibility of the stethoscope tubes would allow for this to be placed into any pocket or bag.